As an effective energy conversion and energy storage device, lithium batteries have always attracted much attention. Its characteristics such as high working voltage, high energy density, high specific energy, high specific power, smooth discharge, and no memory effect are widely used in various applications.

Although lithium batteries have achieved great success in 3C products, their use in power applications and energy storage is still in its infancy. With the outbreak of new energy vehicles, the demand for lithium batteries continues to rise, while the cost and performance requirements are also constantly increasing. It can be said that the lithium battery industry is full of opportunities and challenges. The degree of automation and intelligence of the lithium battery production line will directly determine the competitiveness of lithium battery companies in the future. Therefore, domestic lithium battery manufacturers’ equipment automation upgrades have become the only way to enhance the competitiveness of enterprises. Whoever has the production capacity of high-end automation equipment first will be the first to gain.

At present, lithium batteries are developing in the direction of safety and standardization. The high-precision, high-efficiency, serialization, and highly automated production lines of equipment will become the general direction of industry development. Fully automated and intelligent lithium battery production equipment will ensure that the lithium battery produced has better consistency, high reliable safety performance and through-through yield on the basis of ensuring the lithium battery production process, thereby reducing production costs.

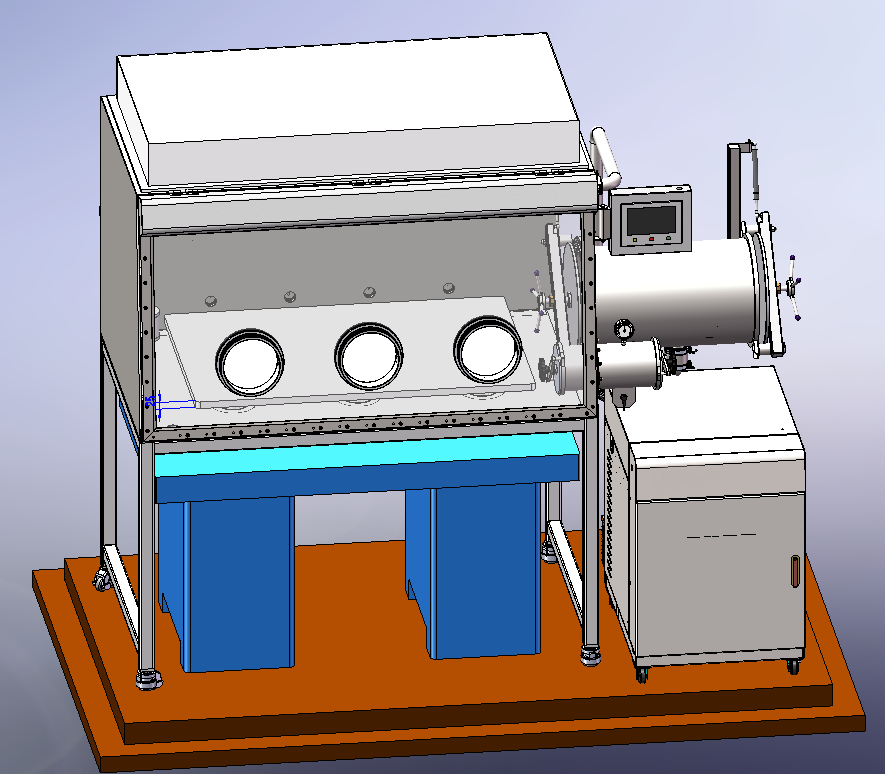

The automated production line of Lithuanian lithium battery can realize the fully automatic production of lithium battery, which greatly improves the production efficiency and saves the labor cost. This production line can realize full-automatic code scanning-filling-weighing-rehydration-sealing operation in the super purification glove box, realizing efficient and completely unmanned automated production, greatly saving labor costs, greatly improving productivity and product quality and yield. To maximize the benefits for customers, this production line is a revolution in the production of lithium batteries / supercapacitors. The entire battery production process can be automated.