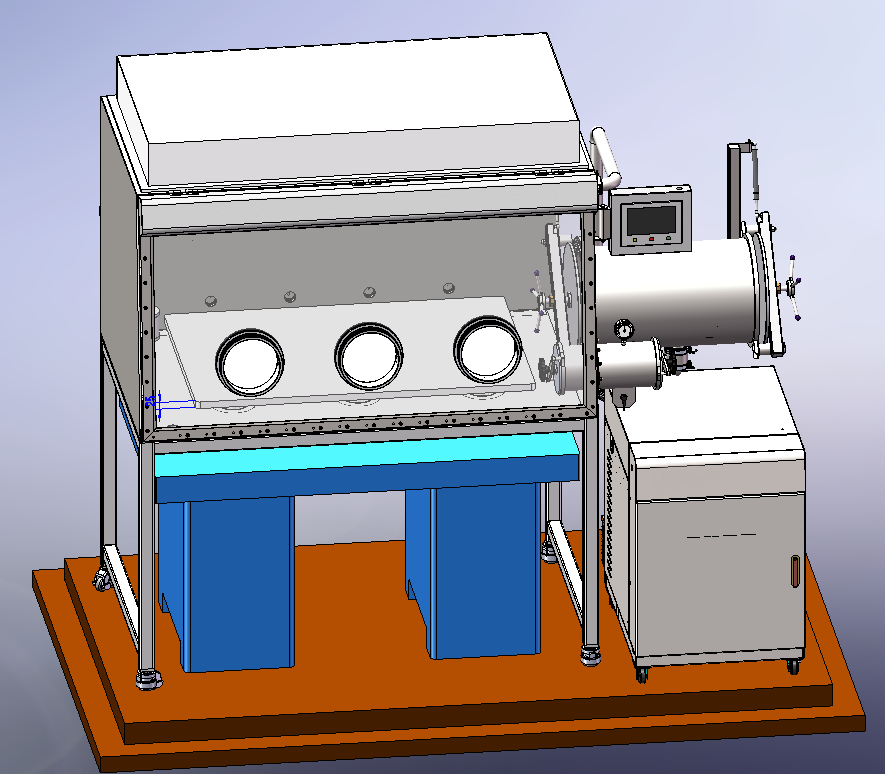

- Oven and glove box

- The oven is equipped with one or more shifts of production materials at a time, and is baked and dehydrated;

- Automatic material transfer in the oven

- After the oven material baking process is completed, it is transferred to the glove box cooling area for cooling at a time;

- After the cooling is completed, the material is picked up by an automatic material picking robot and transferred to the processes of liquid injection, soaking, standing, sealing, etc. These processes are automatic production processes;

- After the above operation is completed, exit the warehouse through a large warehouse;

- After all the materials have been transferred to the glove box, close the door with the glove box, open the outer door, and reload the material for the next shift of the material oven and the original process. The production line does not need to be connected with multiple ovens. It can bake one shift or multiple shifts at a time, saving production time, reducing production links, and avoiding secondary pollution in other operation methods. The product quality is ensured, and the use of the manipulator saves a lot of labor and realizes automated production.

Worldwide shipping

Shipping & Returns