The inert gas-operated glove box is a convenient and high-quality glove box system to meet your specific inert atmosphere application needs. The main function of this system is to remove O2, H2O and organic gases; it is widely used in ultra-pure environment without water, oxygen and dust. The standard Universal includes a single-column inert gas purification system (automatic regeneration) that can purify the glove box atmosphere to a water and oxygen content of less than 1 ppm. The system is made of all stainless steel pipes.

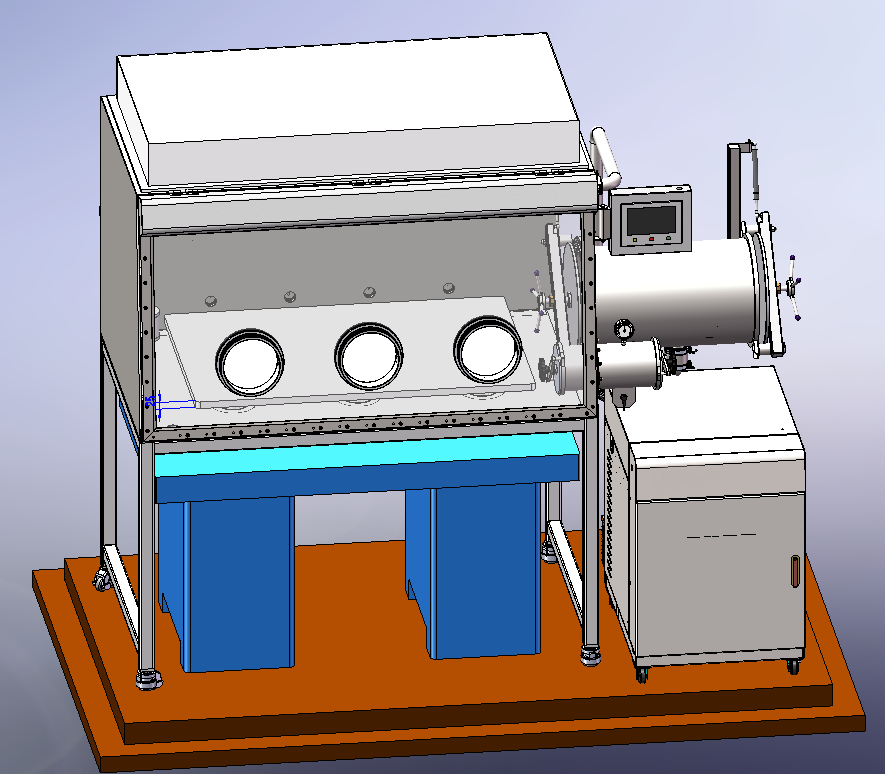

Itex inert gas glove box is composed of glove box body, purification unit, transition cabin and control system. The purification unit is divided into purification column, circulation system, regeneration, vacuum pump and valve. The transition cabin is divided into a large transition cabin and a small transition cabin. The control system functions (including self-diagnosis, power-off and self-starting features, with pressure control and adaptive functions, automatic control, cycle control, and password protection), automatically record system data.

Features

Quick deaeration and deaeration, available water, oxygen content <1ppm (under standard conditions, empty box operation)

Can be customized according to customer requirements, can be integrated according to user needs organic solvent adsorber, refrigerator, heating furnace, micro projection system, installed cold trap, low temperature bath, solvent purification system, dust removal system, pressurization system, evaporation table, glue rejection Machines and vacuum furnaces.

Application field

The inert gas glove box has a modular structure, which is convenient for combination. It can be directly integrated with laboratory instruments, vacuum coating, automatic production lines and other equipment. The glove box system is mainly divided into R&D type (single type) and production type (combination type). Glove boxes of different specifications are selected according to different use places. The products are widely used in physical and chemical research, powder metallurgy, nuclear technology, special welding, OLED and PIED research, pharmaceutical industry, material processing, R&D and production of special lamps, fine chemicals, polymer materials and other industries.