Materials needed: N2:H2=90:10 binary gas bottle, one pressure reducing valve, used to adjust the pressure of binary gas cylinder

Precautions:

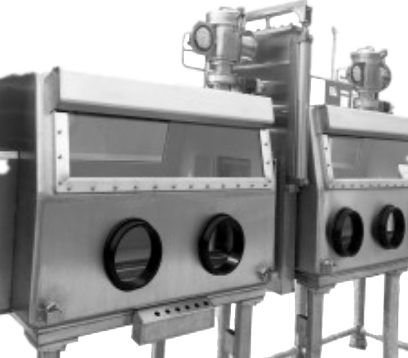

1. The left and right sides of the glove box are controlled separately, regenerating separately, without interfering with each other. That is, there is a set of regeneration gas inlets and outlets on each side.

2. The initial pressure of the binary gas cylinder used for regeneration must be above 8MPa, and normally it should exceed 10MPa. Otherwise, the gas volume is not enough and the regeneration cannot be completed.

Steps:

1. Connecting pipelines: There is a set of regeneration cycle pipelines leading out from the back of the glove box console, which are labeled with “regeneration gas inlet” and “regeneration gas outlet” labels. Connect the intake pipe to the binary gas cylinder (reducing valve), and extend the outlet pipe to a well-ventilated place (the binary gas and a small amount of water will be discharged here) 2. Operate on the control panel, close the cycle, keep the vacuum pump open, and enter Set the menu and click Replay.

It takes 16 hours to regenerate, divided into the following stages:

1. Click to complete the gas test from 00:00-00:02 within 2 minutes after regeneration, and make sure that the pipeline is unblocked. At this stage, the gas valve opens automatically. Please check if there is an in and out. 00:02-00:05 The gas valve is closed and the gas supply is stopped.

2. From the 5th minute to the 3rd hour 00:05-03:00, the system will automatically start heating the purification column

3. In the next 2.5 hours, that is, 03:00-05:30 is the main stage of regeneration. Starting from 03:00, the console valve will automatically open to introduce binary gas, and adjust the pressure reducing valve to maintain a flow rate of 20L/ about min. At this stage, someone needs to watch, and the flow will fluctuate. Adjust the pressure reducing valve to control the flow in time (it is best to use a pressure reducing valve that can accurately control the flow).

4. At the end of 05:30, the gas valve is closed and the pressure reducing valve is closed. The binary gas cylinder can be removed from 05:30 to 16:00, and the heating of the purification column is also stopped. No operation is required. Do not open the loop.

5. After 16:00, the regeneration is complete, and the loop can be turned on.

Note: 1. The gas must be switched on and off strictly according to the above time period. The gas valves described above are all automatic gas valves in the glove box console. Manually adjust the pressure reducing valve to match the above process.

2. If the regeneration operation is not entered after pressing the regeneration button, confirm whether the cycle has been closed and the vacuum pump has been turned on as required. If not resolved, try to enter the password 1979

3. All times are subject to the time displayed on the control panel. The step1, step2?? displayed on the control panel do not necessarily correspond to the opening and closing of the air valve. For example, if the panel displays from step 2 to step 3 at 02:00, the air valve is not automatically opened at this time, and the air cylinder is opened for ventilation flow. The table has not changed, this is normal, please wait until 03:00.

4. It is a normal phenomenon that the water oxygen content rises during the regeneration process. Since it cannot be inflated, please do not operate the glove box to avoid the pressure drop. After the regeneration is over, open the cycle as soon as possible at 16:00 to start purification. If it is midnight and no one is left behind, you can open it early the next morning.

5. There is a purification column in the glove box dedicated to the adsorption of organic solvents. The purification column has a limited capacity. Try to avoid using a large amount of organic solvents in the glove box for cleaning and other operations.