Worldwide shipping

Shipping & Returns

Quality assured

Find retail locations

Expert support

For All Your Questions

Fast and secure

For All Your Questions

Shipping & Returns

Find retail locations

For All Your Questions

For All Your Questions

Shipping & Returns

Find retail locations

For orders above $100

For All Your Questions

In case we have not met, I’m Alexa Williams, Ask Alexa. I have worked here at Etelux for almost 15 years establishing great relationships with our customers and partners. Throughout my career at Etelux, I have had the pleasure of advocating for you, the customer, to make sure that you are taken care of. Most of the time, I am the friendly voice that answers the corporate phone line, so if we have not met in person, I’m sure we have talked. This form is to reach me directly, and I will respond as soon as I can. You can ask me anything, such as questions about our enclosures, help with which replacement parts to order, certification questions, etc…

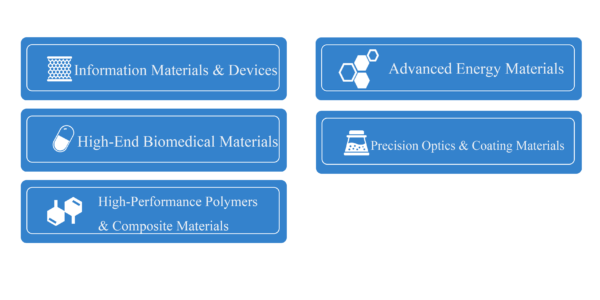

Serving the Chinese scientific industry for over 15 years, discover how quality products, competitive pricing, and next day delivery allow us to achieve our mission “Enabling Technology for a Better World ".

Ultricies eu consectetur vitae donec scelerisque ante a ut morbi aptent tincidunt est non sagittis ut.

Shipping & Returns

Find retail locations

For orders above $100

For All Your Questions

This system realizes triple environmental control inside a glove box:

Ultra-pure inert atmosphere

A closed-loop purification system maintains ultra-high purity inert gas (e.g. N₂, Ar) in the chamber, with typical H₂O and O₂ levels < 0.1 ppm, effectively isolating the environment from moisture and oxygen.

Cleanroom-grade particle control

An integrated clean system – typically ISO Class 5 (Class 100) or better, using vertical laminar or mixed turbulent flow – continuously circulates and filters the internal gas via FFUs (fan filter units). This removes micro- and sub-micron particles generated during operation, preventing contamination of nanomaterials, thin films and sensitive samples.

High-precision temperature and humidity control

A dedicated air-conditioning module provides stable temperature and humidity control over the entire internal volume, solving traditional issues such as glove box temperature drift with ambient conditions, local hot spots and coarse humidity regulation.

The system simultaneously prevents chemical contamination (oxidation, hydrolysis caused by H₂O/O₂) and physical contamination (particle-induced pinholes in films, device short circuits). This is critical for fabricating high-performance optoelectronic devices (e.g. solar cells, LEDs) and for ultra-clean surface studies.

Stable temperature and humidity ensure extremely consistent material properties (e.g. solubility, viscosity) and process parameters (e.g. solvent evaporation rate, thin-film formation kinetics), dramatically improving experimental reproducibility and data comparability. As such, it serves as a core infrastructure for top-tier research institutes and high-tech enterprises pursuing disruptive innovations in advanced materials.

When you select Etelux Solutions as your technology provider, you'll be placing your Glovebox& Vacuum Coating Equipment infrastructure in the hands of experienced, trained professionals. We take a different approach and the results are clear. People love our team and the services we provide.

We have more than 16 years of glove box manufacturing experience and have been awarded 35 technical patents.

Our R & D team is committed to innovative technology. Through comprehensive international technical exchange & collaboration and through continuous application of cutting edge engineering and manufacturing techniques we create “state-of-the-art” products and customized solutions to serve the diverse needs of our client base.

We have deployed an ERP system that vigorously and systematically controls, tracks, and monitors the fulfilment process from placement of an order through design, manufacture delivery, installation & commissioning, and post-sale service.

Gantry Machining Centers, CNC Turning Centers, Welding Robots, CNC Press Brake, Laser Cutting Machine and Helium Mass Spectrometer leak detection are among the equipment we use every day to produce our glove boxes. These facilities and equipment not only ensure the consistency of the products, but they also enable us to shorten the prototyping cycle of new product R & D and product customization.

The key to our client service is our seamless integration of deep industry and functional expertise with tools and capabilities to support execution and make change happen—on a global scale.

A fluid circulation circuit formed by copper tubing is embedded in the inner wall of the glovebox. Using an external temperature-controlled circulator, the heat-transfer fluid is heated or cooled to a setpoint temperature and then pumped through pipelines into the copper-tube network integrated inside the glovebox. By exchanging heat with the metal panels or internal modules, the copper tubing enables precise local heating and cooling of specific zones inside the chamber, thereby achieving accurate temperature control of the core working area.

An integrated safe power supply provides standard electrical outlets inside the glovebox for devices such as magnetic stirrers, sensors, and small instruments, greatly facilitating internal operations.

In this way, the system simultaneously addresses two key requirements: atmosphere protection and precise temperature control, while maintaining very smooth and user-friendly operation. It is a high-end, fully customized workstation designed for advanced scientific research and fine chemical processing, offering superior experimental conditions for handling sensitive materials.

This system integrates multiple independent functional modules and glovebox types into a complete solution for special material processing.

The main working chamber features a three-glove-port design, allowing two operators to work simultaneously, which is ideal for coordinated machining, assembly, or measurement tasks. A compact precision CNC lathe or dedicated turning head is installed directly inside the glovebox, enabling operations such as OD turning, facing, grooving, and boring on bar stock under an inert atmosphere.

The lathe spindle, guideways, and control system require power, compressed air, and data connections, which are routed into the chamber through dedicated sealed electrical feedthrough plates or corrugated-tube interfaces.

An auxiliary chamber is connected to the main chamber. Chips, waste material, or finished parts generated during machining can be transferred from the main chamber to the auxiliary chamber. In the auxiliary chamber, a precision balance is used to weigh materials in order to calculate material utilization, record finished-part weight, or prepare raw materials for the next process step.

By seamlessly combining inert-atmosphere protection, precision manufacturing, and quantitative analysis, this system represents a high-end and sophisticated glovebox-based solution for advanced applications.

The Etelux integrated tube-furnace single-side dual-station glove box combines a high-temperature tube furnace with a fully sealed inert atmosphere workstation. Samples can be loaded, heated and cooled along one continuous line without leaving the protected environment. The dual glove ports allow two operators to work at the same time, improving efficiency for new-materials R&D and small-scale preparation. This configuration is ideal for solid-state battery materials, functional ceramics, catalyst powders and other air-sensitive samples that require precise thermal treatment under controlled atmosphere.

No account yet?

Create an Account