Worldwide shipping

Shipping & Returns

Quality assured

Find retail locations

Expert support

For All Your Questions

Fast and secure

For All Your Questions

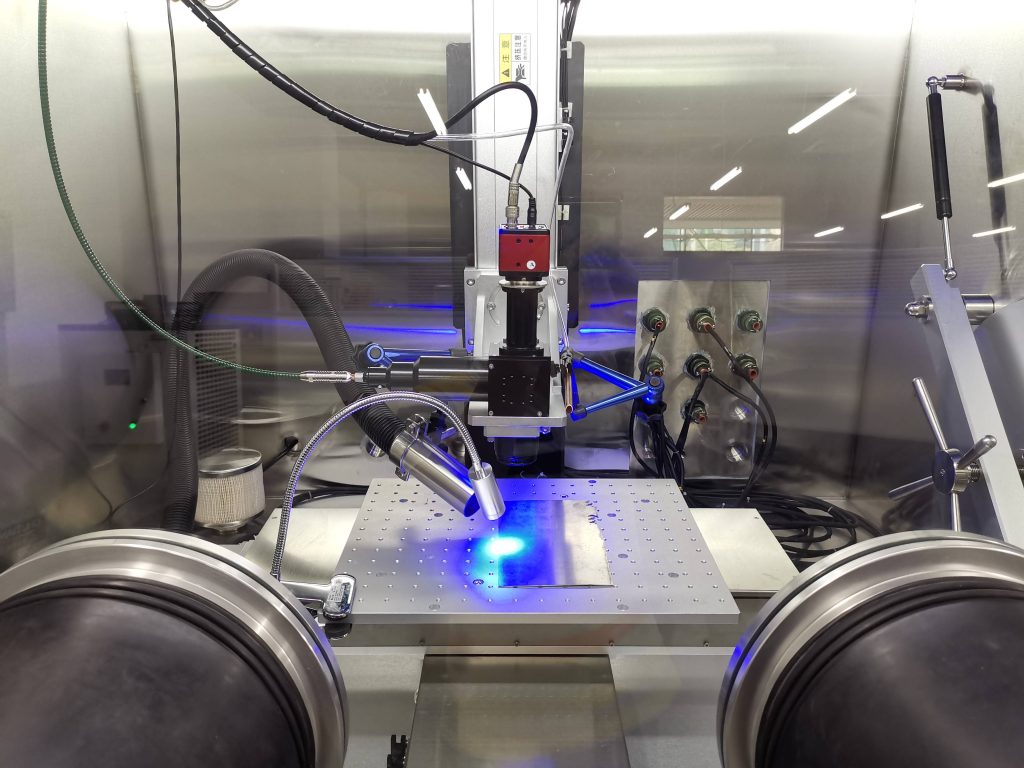

One of the most deadly aspects of the precision laser welding process is the problem of dust. Even the smallest dust particles can have a significant impact on the welding process. That’s why laser welding glove boxes are generally equipped with specialized dust removal systems.

The dust removal system removes the small amount of fumes and dust generated during the laser welding process.

The glovebox is equipped with a 2m long DN40 pumping hose that can be quickly replaced and fixed at least three points in a suitable position inside the box.

The dust removal system adopts frequency converter to control the start/stop and speed regulation of the 90m³/h circulating fan of Germany Siemens, which can be controlled by PLC touch screen. The extraction port is separated from the circulating system, and the return port is shared with the circulating system. Internal DN40 stainless steel piping. The dust removal system does not affect the normal work of the circulation system.

Glove box adopts high efficiency filter with 0.3 micron screen.

Observation windows are opened on the filter shell structure, and manual shut-off valves are installed at the inlet and outlet ends for easy observation and replacement of filter elements.

One-piece closed form, the structure is as compact as possible, easy to transport and sealing.

In addition, the glove box is set to control the fan start-stop control interface to the customer’s work control system, in order to control the start-stop of the dust removal with the laser work linkage, to provide interface definition.

Working Principle

1、Welding is formed by heating the welded metal with laser beam to fusion above the melting temperature.

2、The basic structure of laser welding machine includes laser, welding head, cooling system, numerical control device and operation software.

3、Laser seal welding also needs special atmosphere environment welding or vacuum environment welding.

Product Advantages

1、Dense structure, excellent compressive strength.

2, laser, motion platform and other major equipment using internationally recognized brands to ensure the quality of equipment and equipment operation stability.

3、PC machine intelligent control, CCD image positioning, can be accurately located tracking welding, to ensure the welding quality.

4、Laser welding pulse waveform can be programmed, the control system turns at a uniform speed, and the weld is uniform.

5、Controllable laser welding start and end point energy slow rise and slow fall.

Product Application

1、MOCVD technology in semiconductor industry

2、Microelectronics, laser and plasma welding

3、YAG laser welding

If you have any questions, please contact Etelux.

No account yet?

Create an Account