Worldwide shipping

Shipping & Returns

Quality assured

Find retail locations

Expert support

For All Your Questions

Fast and secure

For All Your Questions

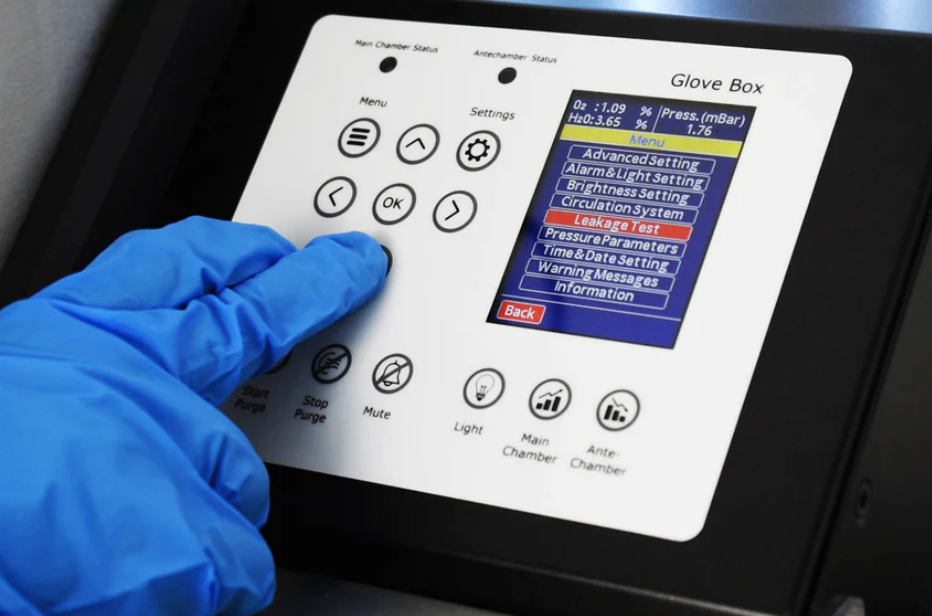

In simple words:

Leak rate = pressure loss over time × box volume.

Unit: mbar·L/s

Example:

Leak rate = (1 mbar × 1000 L) / 1000 s = 1 mbar·L/s → too high.

You want numbers much smaller than that.

Typical practical targets:

| Use case | Leak rate (mbar·L/s) | Meaning |

|---|---|---|

| General R&D / teaching | ≤ 1×10⁻² | Fine with a healthy purifier |

| Battery / advanced materials | ≤ 5×10⁻³ | Faster recovery after transfers |

| Very air-sensitive work | ≤ 1×10⁻³ | Plus strict transfer discipline |

If you are better than 1×10⁻² mbar·L/s and still suffering, look at transfers / solvents / purifier first.

You need:

Steps:

Very common情况:

常见原因:

No account yet?

Create an Account