In order to protect the environment, energy conservation and environmental protection, and the promotion and application of green energy, one of the ways to protect the environment is to expand the use of electric vehicles, reduce the use of fuel consuming vehicles. The main bottleneck restricting the development of electric vehicles is the life of the power battery.

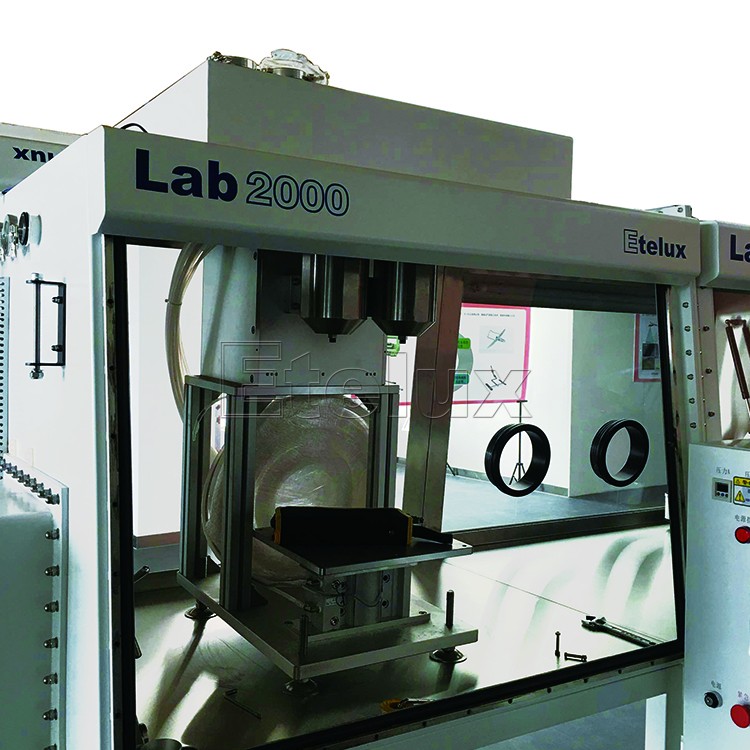

Then, a lithium battery production line, an integrated production line, is provided, which is composed of an oven, a cooling glove box, a liquid injection glove box, a buffer glove box, an extrusion (static) vacuum chamber, a sealing glove box and a discharge vacuum chamber. The electric core realizes automatic transmission in the above operation.

The function of the oven is to realize the vacuum drying of the battery. The function of cooling glove box is to cool the battery. The function of glove box ground is to provide a water free and oxygen free operation environment, and to complete liquid injection and sealing operation in glove box.

The oven and cooling glove box adopt seamless butt joint to ensure continuous production in a controllable, water free and oxygen free environment. All hatch doors are opened and closed automatically, controlled and operated by Siemens PLC touch.

Advantages of the integrated lithium battery production line: seamless connection between oven and glove box, continuous production, fast cooling speed, anhydrous and oxygen free operation environment, automatic transmission and other functions, MES manufacturing execution system, low cost.