Lithium batteries have the characteristics of high specific energy, low self-discharge rate, good high and low temperature performance, long charge and discharge life, and no memory effect. At present, it is widely used in mobile phones, notebook computers, digital cameras, electric vehicles, power tools, and new energy vehicles. At present, when most manufacturers inject electrolyte into batteries, they are completed by the following process: a certain amount of liquid is evacuated, and the battery is discharged. This type of injection is a sleeve type, which wastes a lot of labor. , The production efficiency is low, prone to the risk of side leakage of the sleeve, etc. At the same time, because this method of injection uses quantitative injection, the injection amount of each injection is the same, and then the more injections, the later, It is more and more difficult for batteries to absorb the electrolyte, causing the electrolyte to easily enter the vacuum system, causing waste of the electrolyte, corrosive to the liquid injection equipment, and increasing production costs.

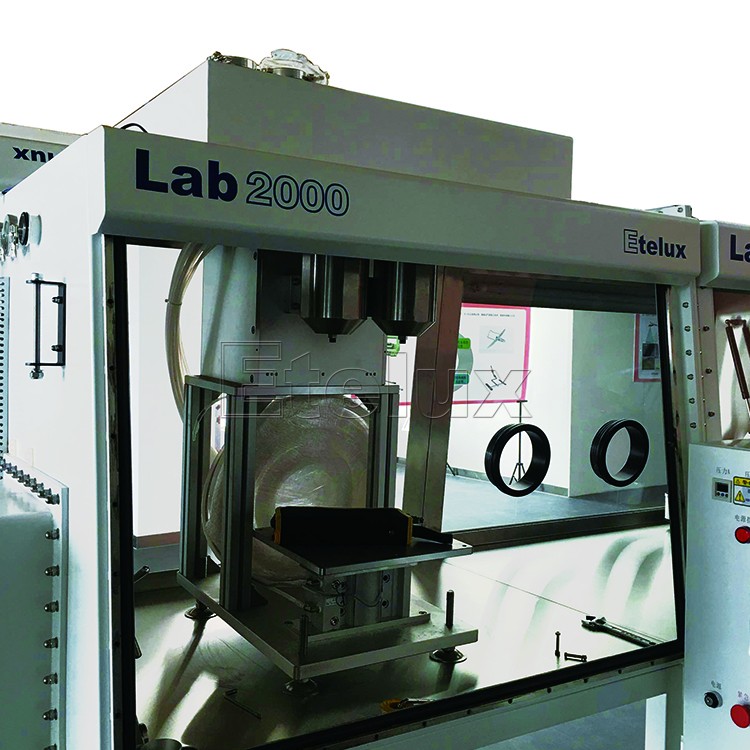

In order to solve the shortcomings of the existing technology, the lithium-ion automatic production line invented by Mi Cairo provides a fully automatic code scanning-injection-weighing-rehydration-sealing operation to achieve highly efficient and completely unmanned automated production, greatly saving labor costs and greatly Improve productivity and product quality and yield to maximize customer benefits.

The technical effect of the Etelux lithium battery automatic production line: it can improve the liquid injection efficiency, liquid injection qualification rate and liquid injection accuracy of lithium batteries; it can also reduce the waste of electrolyte, reduce the corrosion of liquid injection equipment, and reduce production costs; it can increase productivity.

Worldwide shipping

Shipping & Returns