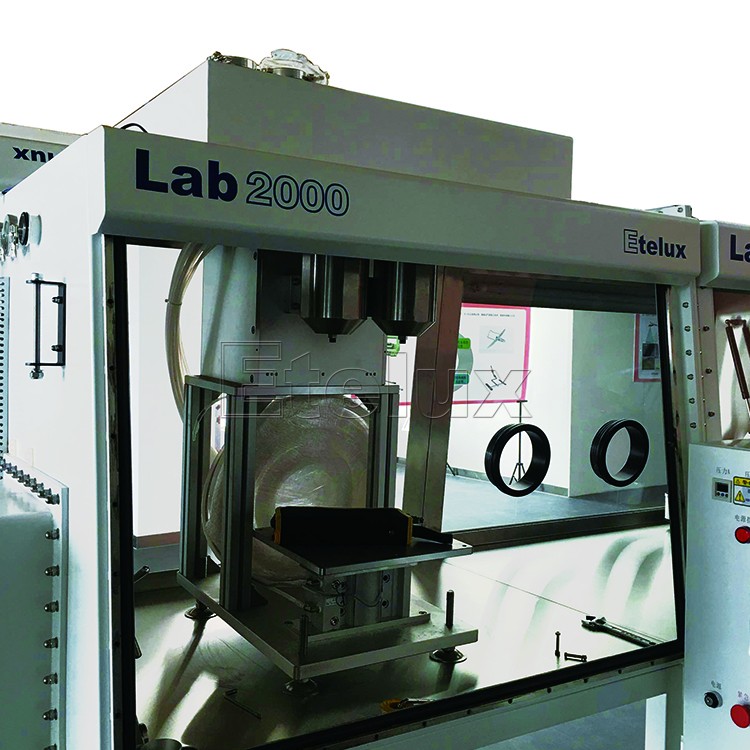

- The integrated production line is composed of oven, cooling glove box, liquid injection glove box, buffer glove box, extrusion (standing) vacuum shelter, sealing glove box and discharge vacuum shelter.

- The electric core realizes automatic transmission in the above operation.

- The function of the oven is to realize the vacuum drying of the battery.

- The function of cooling glove box is to cool the battery.

- The function of glove box ground is to provide an operation environment without water and oxygen, and to complete the liquid injection and sealing operation in the glove box.

- The oven and cooling glove box adopt seamless butt joint to ensure continuous production in a controllable, water-free and oxygen-free environment.

- All the hatch doors are opened and closed automatically, controlled and operated by Siemens PLC.

Advantage:

- The oven and glove box are seamlessly connected to realize continuous production,

The oven and glove box are connected seamlessly, and the earth core is always kept in the environment of the glove box without water or oxygen after baking.

- Fast cooling speed

The whole production line includes cooling glove box, which has fast cooling speed and low cost

- Operating environment without water or oxygen

Ensure that the process of cell from baking to liquid injection and sealing are all operated in a controllable water free and oxygen free environment, providing the most solid protection for the quality of battery.

- Automatic transmission and other functions

It can realize automatic production of battery, greatly improve production efficiency and save human capital

- MES Manufacturing Execution System

The configuration of MES manufacturing execution system realizes information production

- low cost

Customers do not need to build drying room and purchase wheel dehumidification system, saving investment cost and operation cost.

working process

- Put the battery into the vacuum oven for baking and vacuumize to minimize the battery moisture;

- The baked battery enters the cooling glove box automatically through the conveying device, and the cooling glove box has a cooling device to make the battery cool quickly;

- The cooled battery can enter the glove box for liquid injection gradually and automatically through the conveying device;

- The ground battery enters into the glove box after liquid injection;

- The battery in the glove box of the buffer enters the extrusion (standing) vacuum chamber to squeeze the battery;

- The battery will automatically enter the sealing glove box and seal the battery after pressing (standing) the vacuum shelter;

- The battery comes out through the discharge chamber, and the whole conveying process of the battery can realize automatic transmission.